Carbon capture, utilization and storage

Carbon capture and storage (CCS) is an essential piece of the puzzle when it comes to reaching net zero. In fact, according to the IEA, we will need to increase our global carbon capture capacity to 1.6Gt CO2 by 2030 and continue raising it to 7.6Gt CO2 by 2050, if we are going to reach our goals on time.

That is why Alfa Laval is pioneering innovative solutions for more thermally efficient carbon capture, combining tried and true technology with brand new solutions. In fact, our broad portfolio of solutions can already reduce energy consumption in a CCS plant by up to 40%.

Optimized CCS process, reduced costs, and energy consumption

Carbon capture processes are energy intensive, with energy accounting for up to 60% of the total operational costs in a CCS facility. But, with the right heat exchanger technology, process optimization support, and thermal integration both up and downstream, you can maximize energy recovery and reduce energy consumption at the same time.

By partnering with Alfa Laval, you will gain full access to the technology and experience needed to find the most efficient heat exchanger solutions.

The CCUS value chain

Alfa Laval plays a crucial role in the CCS value chain thanks to decades of experience working with even the most crucial applications. Especially when it comes to the capturing process. In fact, we have installations in the oldest CCS facilities in the world that are still operating smoothly today.

So, whether you need to capture CO2 from industrial facilities, power plants, or directly from the air via Direct Air Capture (DAC), Alfa Laval has a broad range of products for your process.

Gasketed plate heat exchangers - Boosting energy efficiency in CSS applications

The unique design of Alfa Laval’s compact gasketed plate heat exchangers make it possible for you to significantly improve solvent cooling in your CCS processes. All with less fouling, stress, and erosion on the internal plates.

But that is not all. With Alfa Laval as your CCS partner, you can even reduce cooling water requirements by as much as 30%!

Find out how you can boost energy efficiency in you CCS applications and become part of the solution.

Welded heat exchanger technology can slash total energy costs by up to 40%

If you use an Alfa Laval Compabloc plate heat exchanger as your stripper reboiler, you can utilize the steam generated from flue gas cooling.

In other words, with Alfa Laval you can reduce fresh steam requirements, fuel consumption, and emissions from your steam boiler. Bringing your total energy costs down by as much as 40%.

Find out how much you could save with a full overview of your process.

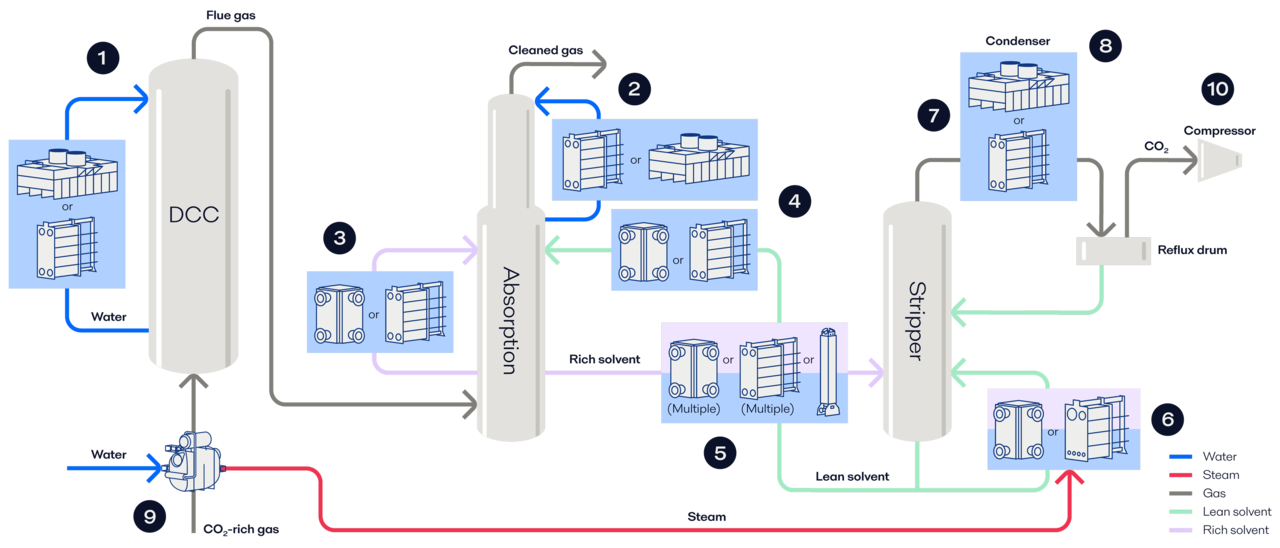

CCS - Liquid absorption

With Alfa Laval heat transfer solutions positioned in the lean/rich interchangers, you can maximize energy recovery in the largest heat recovery duty in your process.

This includes minimizing energy and cooling water needs, while also maximizing CO2 capture efficiency and compressor savings.

Most critical positions:

- Excess heat recovery boiler

- Optimized solvent cooling

- Maximized heat recovery in lean/rich amine interchanger

- Plate heat exchanger for stripper reboiler

CCS - Direct Air Capture (DAC)

Thermal management is also critical when it comes to Direct Air Capture, as the concentration of CO2 in the atmosphere is much lower than the amount emitted in point source capture flue gasses. This means that the developing technology used to capture CO2 from the air consumes a high amount of energy per tonne of carbon captured.

Alfa Laval’s gasketed plate heat exchangers are a reliable solution to make sure that your DAC technologies are optimized with efficiency in mind.

Leveraging heat transfer in the carbon capture process

With the rapid development of carbon capture technologies, selecting the right system for your specific application is more important than ever. Key factors like space constraints, water availability, energy consumption, and CAPEX play a critical role in the successful deployment of your carbon capture technology.

Download our eBook to uncover the best-fit solutions for your post combustion or Direct Air Capture systems, designed to meet your unique challenges.

Download our technical report - Carbon capture with least OPEX and CAPEX

Save over 70,000 tonnes of CO2 from the cement production

Decarbonizing cement industries through CCU with advanced heat transfer technology: the carbon capture is estimated to save over 70,000 tonnes of CO2 from the cement production yearly. With the ambition to be carbon neutral by 2050, Heidelberg Materials has many upcoming decarbonization projects for their plants, taking the lead in the industry.

Accelerating cost-effective carbon capture

Alfa Laval heat exchanger technology has played a central part in over half of the world’s CCUS plants. Our unique Alfa Laval Packinox plate-and-frame heat exchangers are enabling the development of sites that will facilitate the possibilities of carbon capture at large economies of scale. Read this story to learn more about the role heat transfer plays in carbon capture and how we are working with major process licensors and end-users to make it possible.

Enabling e-methanol with CO2 utilization and advanced heat transfer technology

Once CO2 is captured, it can be utilized in downstream processes such as Power-to-X in e-methanol production. Combining green hydrogen with a CO2 source paves the way for e-methanol. Besides being used as fuel or for energy storage, e-methanol is also crucial for decarbonizing large parts of the chemical industry. Alfa Laval offers a unique portfolio of state-of-the-art heat transfer technology to, for instance, enable highly efficient e-methanol production.

Our solutions

Alfa Laval has a broad portfolio of heat exchangers to meet the energy-intensive demands of CCU/S applications. We can help you maximize energy recovery in a range of duties, including for lean/rich interchangers, the largest heat recovery duty in the process. We also offer solutions for minimizing energy and cooling water needs, while maximizing CO2 capture efficiency and reducing the cost for the compressor package and other process equipment.

- Direct contact cooler (DCC)

- Wash water cooler

- Absorption tower pump-around cooler

- Lean solvent cooler

- Lean/rich solvent interchanger

- Stripper reboiler

- Stripper condenser

- Compressor interstage cooler

- Flue gas heat recovery and conditioning

- Super critical CO2 cooler

Heat transfer

Alfa Laval gasketed plate-and-frame heat exchangers

Our Gasketed plate heat exchangers are optimizing heat transfer by large surfaces of corrugated plates drawing heat from one gas or liquid to the other. The high efficiency and an outstanding reliability in a compact design, offers an investment with the most attractive CTO over the product life time. Not to forget the energy saving capabilities and low environmental footprint.

Alfa Laval Compabloc welded heat exchanger

With over 30,000 units handling tough duties worldwide, Compabloc is the market champion when it comes to heat transfer. Its compact design has been engineered for superior reliability and performance, making it easy to both service and install. Plus, our Compabloc family is 3-5 times more efficient than traditional shell-and-tube solutions and secures safe operation of up to 60 bar. Learn more about our range to find out how we have improved our process sustainability with you in mind.

Alfa Laval Packinox plate-and-frame heat exchanger

An Alfa Laval Packinox plate-and-frame heat exchanger is the perfect choice for heat transfer duties in processes with large flows, high temperatures and high pressures. Its superior thermal performance lets you increase energy efficiency, grow profitability and minimize your environmental impact. A single Packinox heat exchanger outperforms systems consisting of multiple large shell-and-tubes, both in terms of heat recovery and investment costs.

Alfa Laval Welded spiral heat exchangers

Alfa Laval spiral heat exchangers are designed to handle the toughest heat transfer challenges. Whether it’s frequent fouling from dirty media, or limitations from pressure drop and floor space, they are the ultimate problem solver for liquid-to-liquid and two-phase duties. The robust, efficient and compact designs keep both installation and maintenance costs extremely low, and they have a proven reputation for almost never fouling up.

Alfa Laval Fusion-bonded plate heat exchangers

Alfa Laval’s patented AlfaFusion bonding technology creates highly efficient, compact heat exchangers made entirely of stainless steel. Virtually maintenance free and capable of handling extremely high pressures and temperatures, they are an ideal heat transfer solution for challenging applications. These include duties with high cleanliness demands, with aggressive media such as ammonia, or where copper or nickel pose contamination risks.

Alfa Laval Gas-to-liquid plate heat exchangers

From exceptionally high temperatures to media with extremely asymmetrical flow rates, Alfa Laval’s gas-to-liquid portfolio handles more than other plate heat exchangers. Built with a revolutionary asymmetric “dimple” plate design, our gas-to-liquid models provide efficient heat recovery and very low pressure drop in gas applications – all within a significantly smaller footprint than tubular technologies.

Alfa Laval Printed circuit heat exchangers

Trust the results from 15 years of proven performance. Alfa Laval printed circuit heat exchangers (PCHEs) combine superior robustness and integrity with an exceptionally high heat transfer rate, in a unit that’s up to 85 % smaller and lighter than comparable shell-and-tube and shell-and-coil exchangers. The unique design results in excellent performance, lower installation and operational costs, as well as improved safety. Each unit is also fully customizable according to your exact needs.

Alfa Laval Ziepack

Alfa Laval Ziepack compact in-column condensers, stab-in reboilers, and stand-alone heat exchangers are engineered for high-performance condensation and evaporation duties, as well as gas-gas services. Their innovative design is perfect for applications requiring low pressure drop and compactness, making them particularly suitable for vacuum or low-pressure services.

Heat recovery

Alfa Laval Aalborg AV-6N boiler

Alfa Laval Aalborg AV-6N is a robust and highly efficient boiler with gilled water tubes which is designed to improve a plant’s overall efficiency by maximizing exhaust gas heat recovery. It is intended for steam and/or hot water production.

Cooling systems

Alfa Laval Wet Surface Air Coolers - WSAC

Alfa Laval Wet Surface Air Coolers (WSAC®) are custom built, closed-loop cooling and condensing systems that combine high performance, low operating costs, compact size and reliable operation. Renowned for their robust design and high efficiency, Alfa Laval WSACs are used in a large number of demanding industries. Their low water consumption and high cooling capacity have made them a popular choice in applications where low temperatures are required for process improvements.

Alfa Laval finned tube air heat exchangers (ACE Air coolers)

With an Alfa Laval finned tube air heat exchanger you get a robust cooler that will deliver high performance for many years to come. Our product range covers most applications in oil & gas, data centers, hydrogen, RNG and CCUS. We supply both standardized and fully customized, engineered-to-order solutions. Thanks to their flexible designs, we can configure our heat exchangers to match your specific operating conditions, ensuring reliable operation, low operating costs and high performance.

Curious about our technologies and solutions in CCS?

Contact us today for more information on Alfa Laval's solutions related to carbon capture and storage (CCS). Our experts are ready to support you.