Clariot

Clariot™ is a vibration condition monitoring solution engineered to address the unique and complex challenges that face hygienic process equipment. Clariot’s advanced sensors, tailored for pumps, agitators, and other rotating equipment, deliver unprecedented overview of machine health. Built to deliver precision and grounded in over 140 years of expertise, Clariot empowers businesses with timely insights and recommendations.

One solution. Easy to install. Simple to scale

- 24/7 surveillance ensures always-on overview

- Simple to install solution gets you running in minutes

- Industry-leading analytics application delivers a seamless user experience

- Less downtime provides better safety precautions on the factory floor

- Timely notifications detect problems early to extend asset lifespan

The Clariot™ condition monitoring system combines unprecedented visibility into your equipment health and over a century of knowledge in hygienic processes to build the industry’s leading predictive maintenance solution.

Installed in just minutes, Clariot goes beyond vibration data to provide your team with actionable insights and the technology to scale it across sites.

Every drop counts with Clariot™

For the industries that provide clean water, food and pharmaceuticals to society, Clariot is the intelligent maintenance solution that spots problems early to maximize performance and minimize downtime.

Enhance operational excellence

Maximize efficiency and profitability by eliminating wasted time and product

Sustainability without compromise

Reduce your carbon footprint, save resources and extend asset lifespan

Confidence with every decision

Rely on industry-specific data for more accurate analysis and assistance

Seamless, smart, simple to use

Remove guesswork with actionable insights and an intuitive interface

How does Clariot condition monitoring work?

Designed for hygienic process equipment, Clariot is a vibration condition monitoring system compatible with pumps, agitators, and other rotating equipment. Clariot is built on over a century of industry insight, so it installs easily and understands your operations.

Simple installment, smarter insights

Monitor

A small sensor is attached to the equipment. The sensor measures vibration and temperature 24/7. The sensor sends this data wirelessly to a nearby gateway.

Analyze

The gateway securely sends data to the cloud, where you can check everything from your phone, tablet, or computer. Industry-intelligent analytics identify root causes of machine failures related to process, installation, and mechanical conditions before breakdowns

Act

Notifications with step-by-step instructions remove guesswork and enable you to plan and to take immediate action

Expand

Alfa Laval’s global presence and scalable solution makes deployment across your plants seamless, enabling improved efficiency across sites

Buyer’s Guide

Get started with Clariot, and download the Condition Monitoring Buyer’s Guide. Identity and select the right condition monitoring solution for your needs, and begin leveraging the benefits of predictive optimization.

Go from install to insight in no time

Clariot™ VX sensor

Installed in minutes, the IoT-connected Clariot VX sensor monitors vibration, device temperature, and run-time to provide 24/7 surveillance. Mounted on the equipment and designed for wet, hygienic environments

Clariot™ Connect gateway

The secure Clariot Connect gateway (formerly CM Connect) and dashboard enables unparalleled visibility into machine health – wherever you are – so you can take actions to avoid disruptions.

Clariot™ analytics

Turn insights into uptime with Clariot’s analytics. Designed for hygienic processes, Clariot offers precise recommendations that eliminate investigations

Talk to an expert

Predict. Prevent. Perform.

With predictive maintenance, Clariot’s 24/7 condition based monitoring system spots problems early, helps your equipment last longer, and saves you resources.

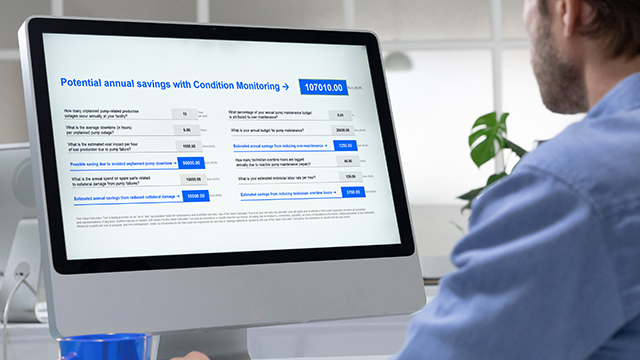

Enter your unscheduled production stops to discover your potential savings.

Pelanggan puas

Animasi

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!