Multi

Engineered for use in most industries, Toftejorg rotary spray heads from Alfa Laval are highly efficient tank-cleaning offer exceptional cleanability, better end-product quality, greater overall output and reduced operating costs.

Cost-effective cleaning

Toftejorg rotary spray heads provide high cleaning efficiency at significantly reduced cycle times to meet the tank-cleaning requirements of various process industries – from the pulp and paper and chemical processing industries to the bioethanol and starch industries. Toftejorg rotary spray heads also provide measurable savings by cutting energy, chemicals and water consumption for virtually any tank size and configuration.

To achieve the best cleaning results, Toftejorg rotary spray heads use an optimized spray pattern to ensure efficient distribution of rinse water to all inner tank surfaces. The high-impact dense spray pattern removes any residue after the production cycle more quickly and effectively than the much more expensive and time-consuming cleaning methods of soaking in chemicals or manual cleaning. Self-draining and self-cleaning, inside and out, all Toftejorg rotary spray head devices comply with Good Manufacturing Practice.

Performance reliability and long service life

Designed for minimal internal pressure loss, Toftejorg Rotary Spray Heads rotate at pressures of less than 0.1 bar; however, the recommended operating pressure is between 2 and 3 bar. For over half a century, rotary spray head technology has proven successful in providing reliable and repeatable cleaning performance and long service life.

Product benefits

- 40% faster cleaning = more time for production

- Dynamic cleaning performance and 360° full wetting

- Saves up 40% of your cleaning cost

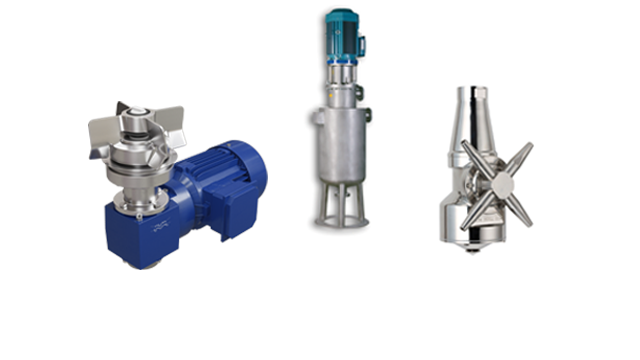

The range of Multi:

Kepala semprotan putar Alfa Laval

Membersihkan dengan kipas yang berputar menghasilkan dampak dan cakupan. Cara ini mengurangi konsumsi cairan dan mempersingkat waktu pengerjaan.

How it works

Toftejorg rotary spray heads use the cleaning fluid itself to provide coverage and impact. The physical flow of the cleaning media causes the rotary spray head to rotate, with fan jets laying out a swirling pattern across the inner surface of the vessel.

These jets provide a combination of physical impact and a variable falling film of cleaning fluid that covers all the internal surfaces of the tank or reactor. The variable falling film has higher heat and mass transfer coefficients than the falling film produced by the static spray ball.

The spray head also cleans itself by directing the cleaning media through the rotating bearing track and onto the neck of the elongated head.

Rotary spray heads are a cost-effective alternative to traditional static spray balls because they use only small volumes of cleaning fluid at low pressure.

These devices are suitable for virtually all kinds of industrial cleaning, including tanks, reactors, vessels and other containers.

|

|

|

|

| Certification | Multi range | Sani range | Sani SB range |

| ATEX | X | ||

| 2.1 material cert. | X | X | X |

| 3.1 material cert. | X | X | |

| Q-doc. | X | X | |

| 3A | X | ||

| EHEDG | X | ||

| Connection | |||

| Clip-on | X | X | X |

| Weld-on | X | X | X |

| Thread | X | X | |

| Surface finish : | |||

| 0.8 ra | X | X | X |

| 0.5 ra | X | X | |

| Spray Pattern | |||

| 180° Down | X | X | |

| 270° UP | X | X | X |

| 360° | X | X | X |

Bagian dari berbagai rangkaian peralatan tangki

Alfa Laval menawarkan rangkaian peralatan tangki lengkap untuk aplikasi higienis dalam produk susu, makanan, minuman, perawatan rumah, perawatan pribadi, bioteknologi dan farmasi.

Untuk rangkaian peralatan tangki yang lebih beragam, jelajahi berbagai kategori produk: kepala jet putar, kepala semprotan putar, aksesoris tangki dan penutup tangki.

Sepuluh tips unggulan - Peralatan Tangki

Berikut adalah beberapa video layanan dan tips untuk menunjukkan cara merawat peralatan tangki.

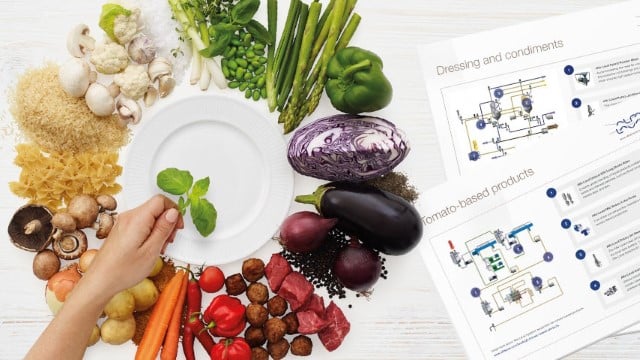

Food Logic

Peralatan higienis Alfa Laval menggabungkan performa tinggi dengan penanganan yang cermat untuk mengawetkan bahan-bahan sensitif dan mengikuti tren industri makanan. Peralatan tersebut mengatasi empat tantangan utama; memasok produk makanan kepada konsumen dengan harga yang kompetitif, mendapatkan hasil maksimal dari bahan baku, mengurangi limbah dan emisi, dan menghasilkan produk makanan yang aman dan higienis.

Katalog produk

Katalog produk peralatan higienis Alfa Laval "Close at hand" berisi selebaran produk, kurva performa, tautan ke animasi, brosur, dan daftar harga untuk keperluan pemesanan.

Portal CAD

Unduh model produk dalam format file CAD Netral atau Asli. Juga tersedia unduhan file PDF 3D.